Can Electric Vehicle Batteries Be Recycled? The number of lithium-ion batteries (LIBs) manufactured was multiplied by 80 between 2000 and 2018. 66% of them were used in electric vehicles in 2018. (EVs). The planned development of electric mobility will increase demand for batteries, with the International Energy Agency estimating that demand for batteries will increase 17-fold between 2019 and 2030.

This situation begs many questions about the materials used to make these batteries: what resources are at stake? What are the environmental consequences of their extraction?

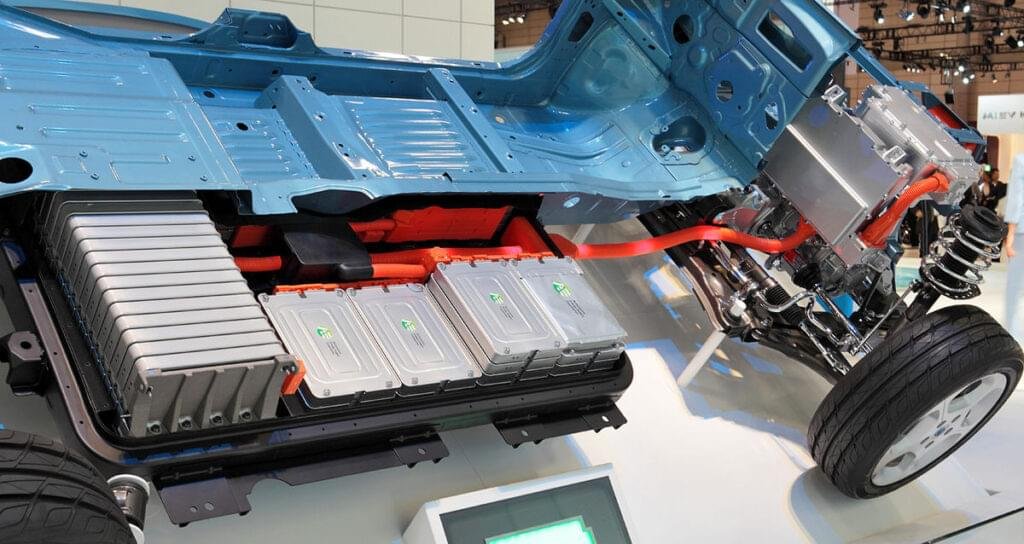

The first thing to know about the materials in the LIBs that are currently used in the vast majority of EVs is that there are various types of battery technology. While all contain lithium, the other components differ: batteries used in telephones or computers contain cobalt, whereas those used in automobiles may contain cobalt in combination with nickel or manganese, or none at all in the case of iron-phosphate technologies.

Because the exact chemical composition of these storage components is a trade secret, determining it is difficult. Furthermore, improvements are made to batteries on a regular basis to improve their performance, so their chemical composition evolves over time. In any case, the primary materials used in the production of LIBs are lithium, cobalt, nickel, manganese, and graphite. All of these have been identified as materials that pose supply and environmental risks.

The issue of supply for these materials is complicated: on the one hand, the value of reserves is subject to geopolitical considerations and changes in extraction techniques; on the other hand, material needs are extremely sensitive to hypothetical forecasts (number of EVs and battery size).

What are the environmental impacts?

The question of the environmental impacts of battery manufacturing is perhaps even more important. Even if there are enough materials, the impacts of their use must be seriously considered.

Studies show that battery manufacturing can have serious impacts in terms of human toxicity or ecosystem pollution. On top of this is the need to monitor labour conditions in certain countries. Furthermore, analysing environmental impacts requires full knowledge of battery composition and manufacturing processes, but this information is difficult to obtain for obvious reasons related to industrial property.

Could recycling the materials provide solutions to limit these risks and impacts?

There are two main families of battery recycling processes that can be used separately or in tandem.

- Pyrometallurgy, which exposes organic and plastic components to high temperatures and destroys them, leaving only metal components (nickel, cobalt, copper, etc.). Chemical processes are then used to separate these.

- Hydrometallurgy, excluding the high-temperature stage. Instead, it only separates the components using different baths of chemically adapted solutions to the materials to be recovered.

The batteries must first be ground to a powder in both cases. The two processes are currently being used on an industrial scale to recycle LIBs for phones and laptops in order to recover the cobalt they contain. This material is so valuable that recovering it ensures the current LIB recycling sector’s economic viability.

However, because not all LIB technologies used in EVs contain cobalt, the economic model for recycling them remains unresolved, and there is no real industrial sector for recycling these batteries. The main reason is a lack of a sufficient volume of batteries to be processed: the widespread adoption of EVs is new, and their batteries are not yet nearing the end of their useful life.

Furthermore, the definition of this end of life is debatable in and of itself. For example, “traction” batteries (which power EVs) are deemed unfit for service when they have lost 20 or 30% of their capacity, corresponding to an equivalent loss in vehicle autonomy.

Can EV batteries have a second life?

There is some discussion about these batteries having a “second life,” which would allow them to be used longer and thus have a lower environmental impact. The first issues are related to the battery reconfiguration and their electric monitoring mechanism. Following that, applications for these “reduced” capacity batteries must be identified. Many experiments have been conducted in this area, and they could be used for energy storage connected to the electricity network.

However, a major player, RTE, the operator and manager of France’s electricity transmission network, believes that this application is unsuitable, both functionally and economically, and instead recommends recycling EV batteries at the end of their first life.

Setting up a recycling sector that can adapt alongside evolving technologies

In order to establish a recycling sector, an economic model that can adapt to a variety of battery technologies without requiring the use of a large number of different recycling processes will be required.

Finally, it should be noted that these environmental impact and recycling issues are not easy to address because the technologies have not yet matured and their long-term viability is not guaranteed. LIBs are evolving at a rapid pace, with lithium-metal battery technologies now being developed, and we are even seeing the arrival of competing lithium-free technologies, such as sodium-ion.

For all of these reasons, the environmental, economic, and social impacts of producing and recycling EV batteries and their materials must be investigated further. It is critical to maintain grassroots and legislative pressure to obtain transparency around manufacturing processes in order to quantify their impacts and identify ways to mitigate them. Future European research programs, including the environmental dimension of new battery development, are also positioned in this area.

However, we should not wait for some miraculous, clean, high-performance, and low-cost battery technology, which is more of a pipe dream. It is critical that we slow the growth of EV battery size, limiting the power, mass, and autonomy of the vehicles themselves.

This implies that we will need to reconsider how we get around, abandoning the car-based model, rather than attempting to replace one type of technology (the combustion motor) with another (the electric motor).